一、Introduction of the simulation training system

1.Product overview

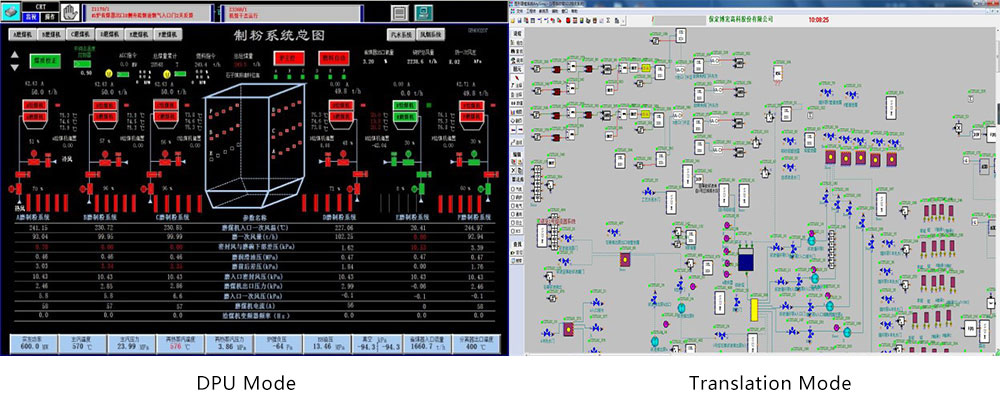

The simulator system can be divided into two modes: translation and virtual DPU, which can be used for training, assessment and skill identification of technical personnel and management personnel such as power plant operators, as well as scientific research and design verification, and provide non-destructive experimental means for scientific research and design engineering technical personnel. The working range of the system include simulation design and optimization of thermal power, gas turbine, hydropower, and photothermal units of various capacities.

2.System use

The simulator system is used for the training, assessment and skill appraisal of technical personnel and management personnel such as power plant operators, as well as scientific research and design verification, providing a better test platform for scientific research,design engineering and technical personnel.

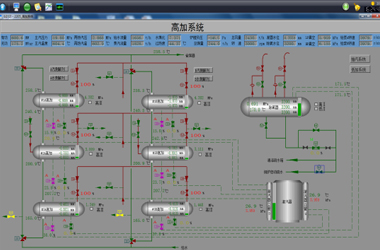

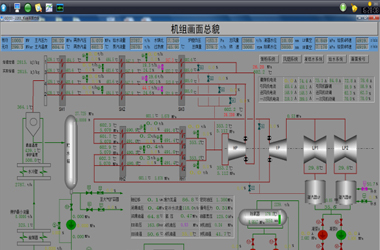

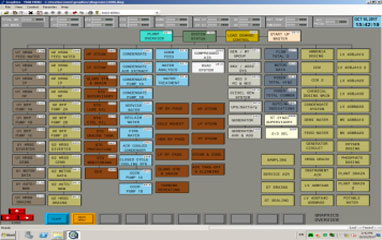

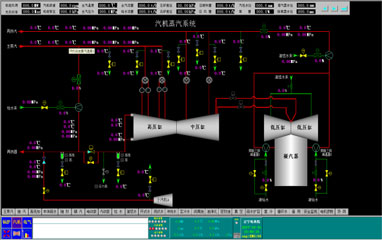

The simulation machine can perform 1:1 simulation on the furnace, machine, electricity, thermal control and other auxiliary control systems. The simulation effect is basically the same as the actual unit operating conditions, which can meet the personnel training requirements.

◆就地操作员站完成运行规程中规定的机组在正常、异常或故障状态下所有就地操作。

4.Main feature

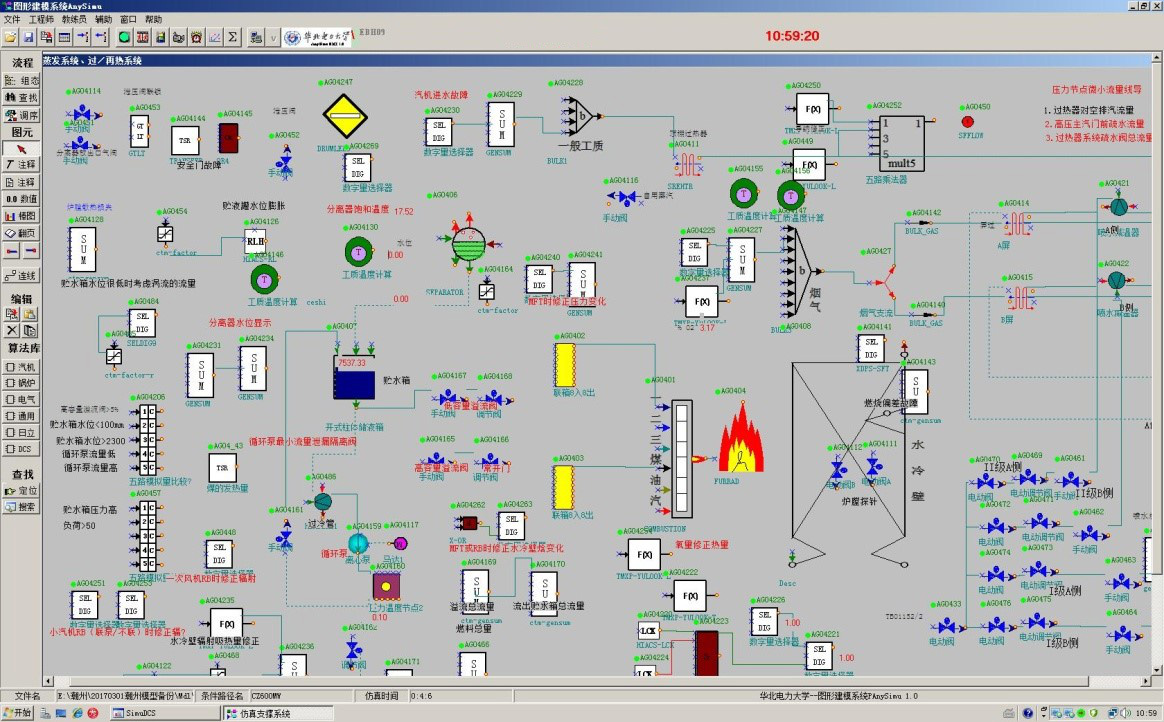

ANYSIMU2.0 is a self-upgrading graphical modeling and simulation support platform with multi-user, graphical, online debugging, openness, and introduction of algorithmic variable coefficients,which can complete the establishment, modification and debugging of the simulation model.

Imake is an in-place operating software that is also self-elevating and can perform all local operations as specified in the operating procedures and local operations that must be performed in normal, abnormal or fault conditions on the local site.

13)Assessment of grades, etc.

二、Service area

The thermal power simulation range covers thermal power, gas turbine, solar thermal, hydropower, and wind power. Thermal power can be simulated in 300MW, 350MW, 600MW, 660MW, 1000MW and other capacity units, including boiler, steam turbine, electric, desulfurization, denitrification,melt water, ash removal and other systems.

2、Gas turbine simulation

The scope of gas turbine simulation includes all systems of gas-fired combined cycle units, including gas turbines, waste heat boilers, steam turbines, generators and auxiliary systems, power plant public systems, auxiliary workshop systems, etc., covering GE, Siemens and Mitsubishi and other manufacturers’ gas turbine simulation.

3、Wind power simulation

The wind power simulation system is not affected by the natural environment. It can simulate a virtual power generation environment according to the characteristics of the simulation object and the natural environment. The power plant simulation model can be established according to the location distribution and variation characteristics of specific wind energy and the actual situation of the generator set.

4、Hydropower simulation

Hydropower station simulation system includes hydroelectric generating set and its control system, electrical main system and system access mode, relay protection and safety automatic device, plant power system, DC system, power system, water system, oil system, wind system, computer monitoring system, central return screen and central control console.

5、Solar thermal simulation

Solar thermal power generation refers to the use of large-scale array parabolic or dish-shaped mirrors to collect solar thermal energy, which provide steam through heat exchange devices, and combine the technology of traditional steam turbine generators to achieve power generation. At present, we are also working on the simulation research of tower-type CSP system, which mainly includes three parts of simulation research, such as heliostat field, endothermic heat storage system and steam turbine system.

6、3D simulation

Prospects:

Traditional system simulation techniques rarely study human simulation of perceptual models, and thus cannot simulate human perception to the external environment. Moreover, humans' ability to understand sensory information such as images and sounds is far greater than the ability to understand abstract information such as numbers and words. 3D simulation technology refers to a realistic and multi-perceived virtual environment based on similar principles, information technology, system technology and its application fields. A technique by which users can use various sensing devices to interact with entities in a virtual environment through their natural skills. It can realize the comprehensive and multi-angle view design details in the 3D scene. The image is realistic and easy to operate. It can not only understand the design details in three dimensions, but also dynamically display the progress of the project. The effect is intuitive and more convincing. Although 3D technology is now used in power plant simulation, it is not objective to adopt 3D technology for a large number of devices and complicated situations. Therefore, in line with the trend of the times, it is necessary to develop a new 3D simulation system.

3D simulation advantages:

①Through the three-dimensional modeling of the main and auxiliary equipment, a high-precision, proportional three-dimensional model is formed, which is consistent with the actual plant layout and equipment height,which let the whole simulation process become three-dimensional, imaged and visualized. Even those who do not understand the power plant can clearly see the structure of the power plant, which can be refined to the wiring that is not easy to see, and can know the external to the entire production process in the power plant.

②It has the equipment disassembly training of main and auxiliary machines, equipment process simulation training, etc., which not only improves the quality of maintenance personnel, but also effectively avoids the production loss caused by operation errors in actual operation, and it’s more convenient to the operation and maintenance of power plants.

③Let us more accurately know the selection of materials and equipment for each device.

④The 3D simulation model can also greatly help the unit design and improve the designers' work efficiency.

7.DCS system optimization

System optimization can improve plant production efficiency, increase the safety and reliability of plant operation, and reduce plant operating costs. The isimu simulation system has complete functions, a wide range of simulations, and high precision of the simulation system, providing a good environment for system optimization. Achieving system optimization is also one of our most important goals. At present, we also undertake optimization projects and have gained good reputation in the industry.